Precision CNC Machining Services

Westfield Machine, Inc., specializes in precision CNC machining services, serving customers in the gas turbine and oilfield industries since 1982. We’re a family owned, customer centric operation, with a hands on approach; this ensures that when you call, your inquiries and concerns will be addressed by the people who have a vested interest in your needs. This approach, combined with a wide array of machining capabilities, position us as a single source turnkey solution from design to finishing.

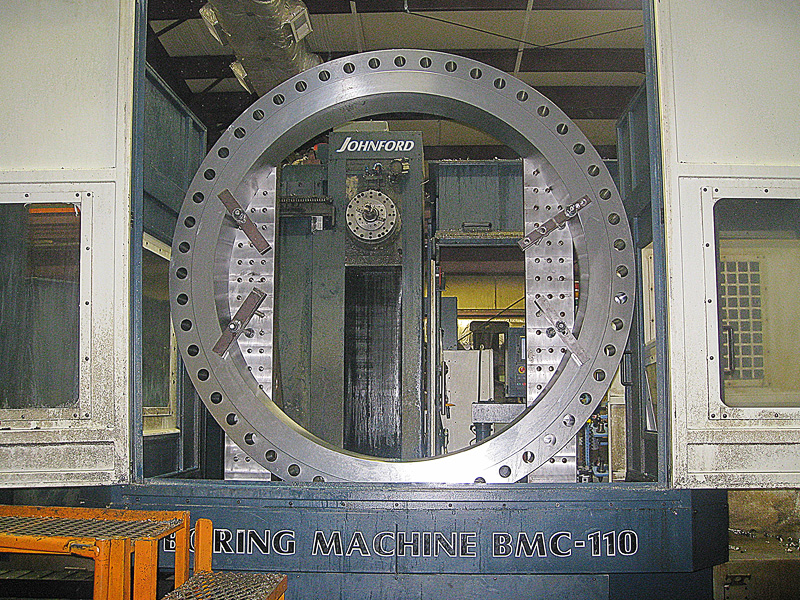

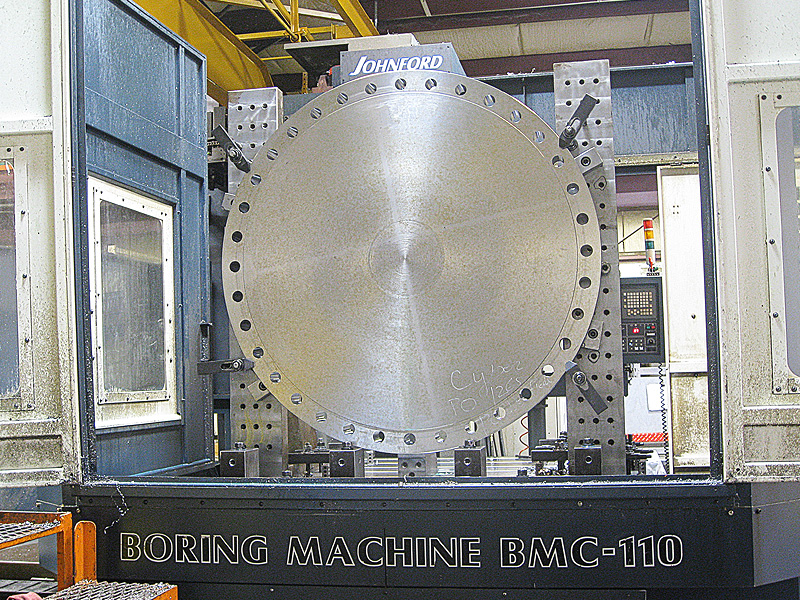

Our state-of-the-art facility is equipped with advanced 4-axis CNC machining capabilities that allow us to achieve tolerances up to ±.001”. Geared towards heavy industry, we can accommodate the machining of large scale components such as boring up to 7’, turning up to 98” in diameter and 160” in length, milling up to 84” in length, 54” in diameter, with a lifting capacity of up to 15 tons.

From gear hobbing to gun drilling and broaching, we can provide virtually any machining operation on materials such as carbon, stainless, and alloy steel, aluminum, nickel, exotic metals, and plastics. In addition, we also provide heat-treating; welding by AWS certified welders, various coatings, and non-destructive testing.

Regardless of operation, all work is done in-house, and in compliance with all major industry standards including: API Spec Q1, API ISO 9001:2015, ASTM, AWS, and any applicable Mil-Spec. To learn more about Westfield Machine, Inc. turn-key solutions, please see the table below or feel free to contact us directly.

CNC Machining Services Project Showcase

Precision CNC Machining Capabilities

- Machining Processes

-

Milling

Drilling

Turning- Contour Turning

- Form Turning

- Taper Turning

- Straight Turning

ID Boring

Gun Drilling

Fine BoringMultiple Lead Threading

Tool (API) Joints

Internal Threading

External Threading

BX Groves

R Groves

Gear Hobbing

Broaching

Spline

FacingParting/Cutting

Counterboring

Countersinking

Pocketing

Profiling

Reaming

Tapping

Thread Milling

Knurling

- Equipment

Vertical

Horizontal

Lathe

- Equipment Capabilities

-

CNC Control Capabilities

Large Swing Lathe

CAD Design Services

CAM Programming Services

Reverse Engineering

- Machinery Axis

4-Axis

- Fixturing

-

Three-Jaw Chuck

Four-Jaw Chuck

Six-Jaw ChuckCollets

In-House Fixturing & Tooling

- Materials

-

Carbon Steel

Stainless Steel

Aluminum

Alloy SteelsNickel

Exotic Metals

Plastics

- Bore

Up to 7 ft.

- Diameter

Up to 98 in.

- Turning Length

Up to 160 in.

- Milling Length

Up to 84 in.

- Width

Up to 54 in.

- Maximum Lifting Capacity

Up to 15 tons

- Tolerances

±.001″

4B on Threads

- Secondary Services Offered

-

Turnkey

Coatings

Heat TreatingWelding

Non Destructive Testing

- Production Volume

Prototype to Large Scale Production Volume Runs

- Lead Times Available

4-6 weeks

Rush Service Available

Additional Information

- Industries Served

Oilfield

Gas Turbine

- Intended Applications

-

Draw Work Parts for Oil Rigs

Blow Out Preventer (BOP)

Risers

Flow Crosses

Recalibration on FixturingInspection Fixtures

Flanges

Double Lead Threading

Subseat Bonnets

Pipe Handling

- Industry Standards Met

-

API Spec Q1

ISO 9001:2015Mil-Spec

ASTM

AWS

- File Formats Accepted

-

SolidWorks

AutoCADGibbsCAM

ShopTalk